Case Study: Ensysce Biosciences

A case study on how Quotient Sciences' integrated Translational Pharmaceutics platform helped Ensysce Biosciences achieve a successful modified release formulation in an accelerated time frame.

Ensysce Biosciences is a clinical-stage biotech company based in San Diego, CA that has a mission to revolutionize the safety and oral delivery of medicines for areas of high unmet need in pain management. Ensysce Biosciences has developed two proprietary anti-abuse and anti-overdose technology platforms, Trypsin-Activated Abuse Protection (TAAP™) tamper-proof technology and Multi-Pill Abuse Resistance (MPAR™) technology, to effectively control the way a drug is turned on or turned off when consumed.

Quotient Sciences was approached by Dr. Lynn Kirkpatrick, CEO of Ensysce Biosciences, to help overcome formulation challenges with the development of a modified release product for PF614-MPAR, the company's leading product intended for the treatment of severe pain. After speaking with a non-integrated, traditional contract drug development and manufacturing organization (CDMO) and enquiring about the timelines for clinical trial manufacturing (CTM) of a single prototype, Dr. Kirkpatrick quickly realized that it would take years to arrive at a successful MR formulation.

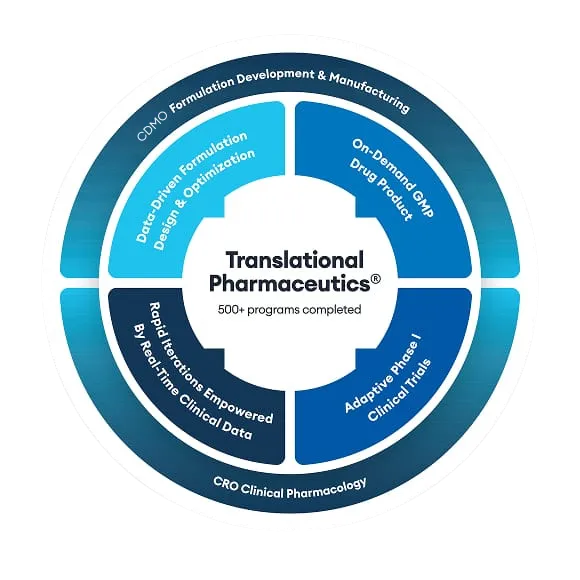

Dr. Kirkpatrick recognized that Quotient Sciences' Translational Pharmaceutics platform, with its ability to integrate formulation development, real-time clinical manufacturing, and clinical dosing under a single organization, would provide her with the flexibility to test multiple prototypes under a single clinical protocol and arrive at successful formulation in just twelve months.

Continue reading our case study with Ensysce Biosciences to find out more about how Quotient Sciences' Translational Pharmaceutics platform accelerated the delivery of their Phase I clinical program.