We asked Clare Preskey, Senior Director of Clinical Operations, and Andy Lewis, Vice President of Pharmaceutical Sciences to share their thoughts on our Nottingham, UK clinical facility.

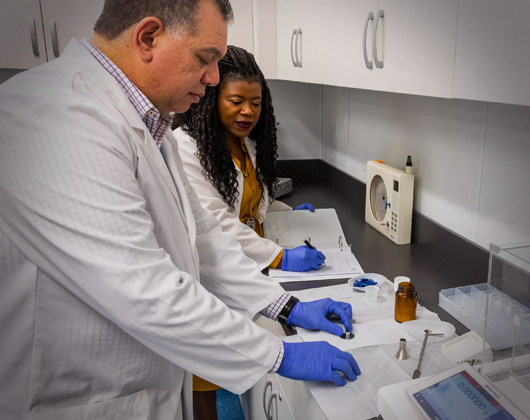

Andy Lewis, Vice President, Pharmaceutical Sciences at Quotient Sciences

As Vice President of Pharmaceutical Sciences at Quotient Sciences, Nottingham, Andy has over 15 years of experience in the pharmaceutical and biotech industry. He currently leads a team of scientists working in formulation development, clinical manufacturing, and pharmaceutical analysis that support client development projects.

What is your role at Quotient and what exactly does a VP of Pharmaceutical Sciences do?

I currently head up the pharmaceutical sciences (PharmSci) department in Nottingham which is focused on developing, manufacturing, and analyzing drug products that are dosed in our clinics to healthy volunteers and patients all over the world in later-stage clinical trials. It’s a huge team effort that also involves dedicated teams managing our supply chain, facilities, equipment, and logistics to meet stringent regulatory and quality standards and to ensure that our medicines are ready and in the right place at the right time.

My responsibilities lie in making sure that our PharmSci team has everything they need to do their jobs to the best of their ability, both now and in the future. Developing the skillsets and careers of our workforce is important to me and a lot of my time is devoted to identifying opportunities for training and personal development.

Tell us about your background training, early career, and how it all has led you to your current role here at Quotient Sciences.

I originally trained as a pharmacist and quickly realized I wanted to work in the pharmaceutical industry during a summer placement in Zeneca (as it was then known) before completing my training at Pfizer. My first role as a scientist was at the University of Queensland in Brisbane, Australia where we were mathematically modeling drug uptake in the liver. We wrote several publications on this work before I returned to Nottingham to do a PhD. During my PhD, we developed in vitro models for drug metabolism and toxicity studies, and together with my supervisor we attempted to commercialize them as an alternative to preclinical animal studies through a University spin-out company.

Following that, I worked for another start-up biotech which was focused on advanced drug delivery. Gaining experience in a start-up environment was invaluable to me as it gave me exposure to many different aspects of the industry that I might not have had the opportunity to at other places. Startups are very fast-paced, entrepreneurial environments where it’s common to challenge the status quo and make risk-based decisions – always balancing time and cost.

In my next role, I moved to a mid-size biotech, Ipsen where I set up a new group to access externally developed innovations in drug delivery. Over 4 years, this group expanded to around 10 scientists, engineers, and technology scouts, with my team split across three sites in France. I had global responsibility for product development which included novel formulation technologies and drug delivery devices. By the time I left, we had projects at every stage of development – from preclinical through to lifecycle management. I was pleased to see one of the products we developed, which I’m a named inventor on, was launched a couple of years ago. Having worked with several different CDMOs on various projects I came to value Quotient’s integrated approach to drug development even more. When a job opening arose at just the right time, I joined Quotient and have now been here for about four years, which have flown, and I have loved every minute of it.

What was Quotient Sciences like when you started and how has it evolved over the years?

When I first started we only had the Nottingham and Edinburgh sites, and PharmSci in Nottingham was about two-thirds the size it is today. We were, and continue to be, very busy, delivering an increasing number of projects every year. We are lucky to have a talented pool of scientists in the East Midlands area of the UK and have managed to recruit and retain some brilliant people to support Quotient’s growth. By the end of my first year, Quotient had acquired facilities in Reading, Philadelphia, and Miami and all of a sudden, we were a global organization. This has given us tremendous development opportunities for our staff and I’m very excited to be part of the next phase of growth.

What do you enjoy most about your role and why? How do you see your role evolving as the business grows?

Undoubtedly, the thing I enjoy most about my role is the group of people I work with. Someone once said, “If you’re the smartest person in the room, you’re in the wrong room”, and I am lucky to be working with some brilliant people across the organization that I learn from. But more than that is the spirit and camaraderie we have here at Quotient, it’s something quite special, and no matter what issue we’re dealing with you’re guaranteed people will be smiling. I’m not sure I’ve ever worked anywhere where so many people are friends just as much as colleagues.

What are the key formulation and manufacturing strengths at the Nottingham site and how do you support customer programs?

In Nottingham, we are experts in formulating small molecule APIs. We can develop, analyze, and manufacture almost all types of dosage forms – from simple drug in capsules to more complex ones such as DPIs and intravenous injections. Solid oral and inhaled dosage forms are our core strength, particularly modified release where we can employ numerous different technologies to obtain the desired performance. We also have specialized capabilities in the development of various radiolabelled drug products – for use in ADME studies, or gamma scintigraphy studies to visualize formulation performance in vivo. A key capability we have is real-time adaptive manufacturing – our cross-functional project teams work together to enable the manufacture and release of a drug product immediately before dosing. This is what we call Translational Pharmaceutics, our unique platform which is an industry disrupter –enabling us to respond to emerging clinical data and optimize drug products more efficiently than the traditional drug development processes.

Can you talk more about Translational Pharmaceutics® and how it is used today by customers?

Translational Pharmaceutics® is unique to Quotient Sciences and is a platform that accelerates drug development by integrating formulation development, real-time manufacturing, and clinical testing.

It was developed here in Nottingham and has been used over the last decade by global pharmaceutical and biotech companies across over 400 drug programs. Put simply it integrates a wide array of activities under a single service provider, reducing the “white space” in development and shortens times between clinical manufacturing and dosing, from months to days.

Translational Pharmaceutics is used to advance molecules across the full development cycle and key applications include:

- Transitioning molecules from first-in-human (FIH) to proof-of-concept (POC)

- Development and optimization of clinical formulations

Has there been any independent research looking at the time and cost benefits of Translational Pharmaceutics?

Yes, recently the prestigious Tufts Centre for the Study of Drug Development in Boston evaluated the time and subsequent financial benefits of Translational Pharmaceutics in a range of different program types. The recent paper by Joseph DiMasi in the Therapeutic Innovation & Regulatory Science (TIRS) Journal, quantified the financial benefits of Translational Pharmaceutics, demonstrating >12 months of acceleration of development and multi-million dollar reductions in R&D costs. This research makes me proud of what we’re doing in helping get new medicines to patients faster and having a positive impact on the health of many thousands of people around the world.

Clare Preskey, Senior Director, Clinical Operations at Quotient Sciences

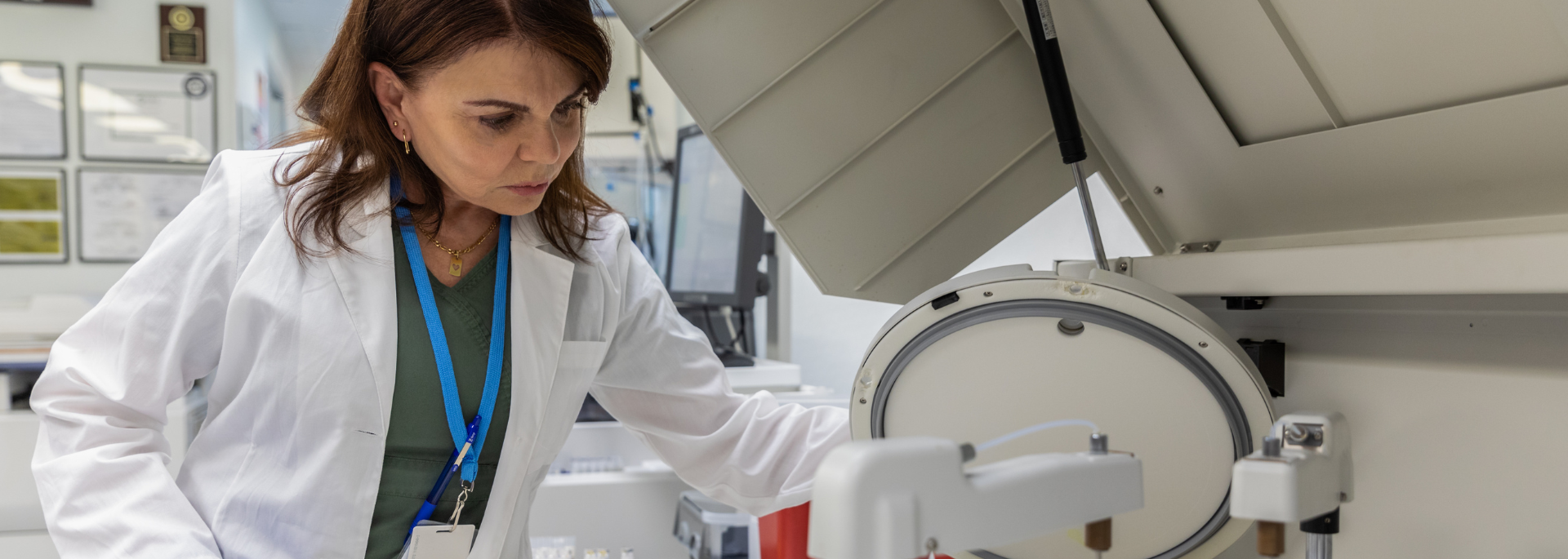

As Senior Director of Clinical Operations, Clare is responsible for the oversight of day-to-day activities that take place in our Nottingham Phase I clinical unit. This includes volunteer screening and management, oversight of our clinical laboratory and pharmacy teams to ensure on-time project delivery, and driving continuous improvement and innovation initiatives.

Looking back to when you were first starting your career, was your goal to be where you are now?

I have always held a passion for science and the study of physiology and pharmacology and I started my career at Quotient Sciences in 2010 fresh out of university as a Clinical Scientist. My key responsibilities were ensuring the well-being of our volunteers and the collection of clinical data.

I then moved into Project Management where I gained valuable experience in customer management and developed a broader understanding of our business. Over the past 9 years, I have held several roles within Project Management with my most recent role being a Team Lead.

I have always held a passion for clinical sciences and operational excellence and my current position of Senior Director, Clinical Operations is a natural fit for me.

What are some of the biggest changes and improvements that you have seen over the years at Quotient Sciences?

When I first joined Quotient, we were a much smaller business with one building containing our 30-bed clinical unit, a GMP suite, and approximately 100 employees. The biggest change is the vast expansion in facilities and capacity, and the evolution of our Translational Pharmaceutics platform. Quotient never stands still; we are always pushing boundaries in the industry, trying to do things better and more efficiently! Despite our growth, the ethos of who we are and what we do has not changed.

The people at Quotient are at the heart of the business; we have a ‘family-like’ culture with tight-knit teams. Close teamwork is imperative when managing complex and integrated projects in short timeframes for our customers. Quotient has always had a big focus on continuous improvement and high-quality standards - I am privileged to work with such committed and talented teams.

What do you enjoy most about your role and why? How do you see your role evolving as the business grows?

The environment at Quotient is dynamic and fast-paced, and every day brings different challenges and opportunities! We work with so many different customers, molecules, and study designs. I love what we do, and I always feel energized to come to work every day, ready to learn and take on the next challenge. My colleagues at Quotient are incredibly passionate and dedicated to every one of our projects and customers. We learn and grow together, expanding our knowledge and gaining new skills. Getting things right the first time is very important to me.

What do you think is one of the biggest successes at the Nottingham site?

As a business, we have grown very quickly, but at the same time, we’ve been able to retain our core values, agility, and integrated processes. One of our biggest successes is that it still feels like a small company, even though we now have over 900 employees across 6 sites globally.

How do the functions of clinical operations and pharmaceutical sciences integrate seamlessly to deliver Translational Pharmaceutics to our customers?

Teamwork is key to any Translational Pharmaceutics program and establishing cohesive communication channels across multiple departments. Our integrated processes have been built up over many years of experience, with SOPs and protocols geared to be highly flexible and adaptive, however, planning is also an essential ingredient embedded in all our operational processes (i.e. kick-off meetings, dummy runs) to ensure the highest quality project delivery that is the right first time.